Cleanroom facilities for the medical market

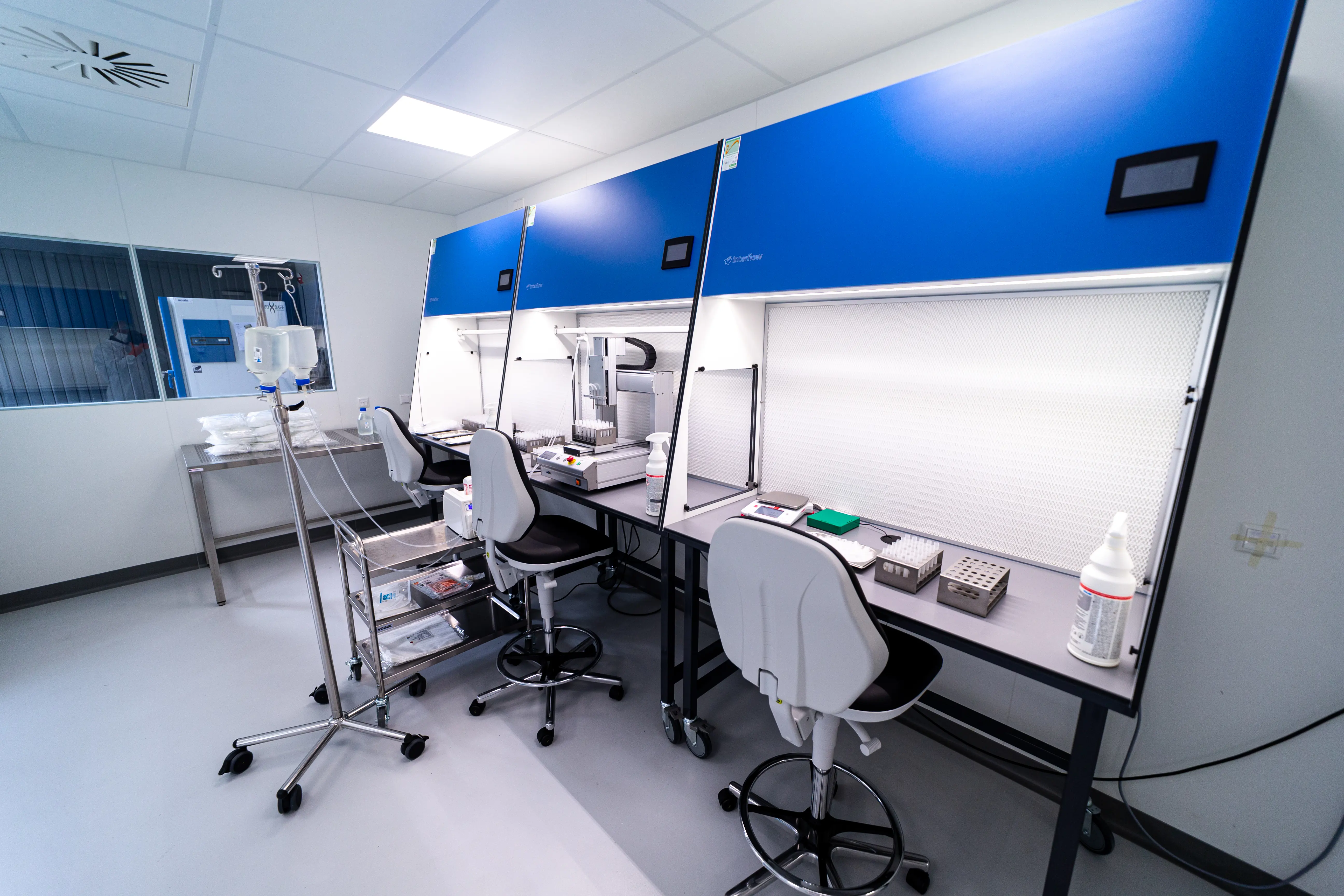

We produce a wide range of packaging for medical applications. Our logical next step has been expanding our filling activities with a cleanroom facility. We have cleanrooms in the US and The Netherlands in the US we have an ISO Class 7 cleanroom and in The Netherlands, our cleanroom meets ISO Class 6 standards, complemented by ISO Class 5 flow hoods.

Are you working in the pharmaceutical, biotechnological, biosciences, microelectronics, or food packaging industry? Then you understand the growing importance of cleanroom installations in manufacturing processes. Sterile production has become increasingly critical, especially in the wake of Covid-19. Learn how combining our co-packing services with sterile production and filling can streamline your operations. Contact one of our specialists today.

Medical Filling

Medical tubes are often filled with a buffer solution. This buffer solution ensures that human tissue, DNA, or bodily fluids have a longer shelf life. The buffer solution must be RNA and DNA-free. In our cleanroom, we can fully automate the filling of liquids. The screw cap or press cap is automatically applied to the filled tube and then labeled.

Trust and Assurance

Filling inside a cleanroom

Medical tubes are frequently equipped with a buffer fluid, which ensures that human tissue, DNA and bodily fluids are preserved for longer. The buffer fluid must be free of RNA and DNA. In our cleanroom, we can fill fluids in a fully automated system. The screw cap or press-on cap is automatically fitted to the filled tube, whereupon the tube is given a label.

Meet your required certifications

DaklaPack serves a wide range of customers across various industries. That’s why we hold all relevant certifications for medical contract packaging. The specific requirements for each sector are strictly upheld. By working meticulously according to established procedures and guidelines, we ensure the quality of our services.

FSSC2000

The recognized international standard for food safety.

SKAL

We comply with the regulations for packaging and storing biological products.

Frequently asked questions

Do you need medical cleanroom packaging services?

Contact us today for a no-obligation consultation with one of our medical packaging experts and learn how partnering with DaklaPack can streamline your operations.